From 2 Hours to 2 Minutes: Advancing the Technology of the AR-15 Rifle Effortless Cleaning & Seamless Shooting Experience

Shooters all know that the fun of training comes at a cost. Along with the cost per round there’s a time expense, every round popped means just that much more carbon and grime build up in your gun; but that’s not all, that carbon and heat also wear down your rifle just a bit faster. So, it’s all about time and money!

Adams Arms is here to save you on both. We start by making our rifles very affordable. Next, we build every rifle with great attention to detail surrounding our Advanced Piston System. Then we sweeten it up with much of the furniture and upgrades you’re going to want, like Rave 140 3.5lb triggers in our P2’s or Proof Research Carbon Fiber Barrels on our P3’s, Kriss Stocks, METAL flip up sights, Ergo Gripz…the list is huge and continues to improve.

Pistons guns are preferred by nearly every fighting force in the world. It’s clear that the old DI systems are on their way out and Piston systems will be the standard of the future. They are just simply better.

The Adams Arms Difference

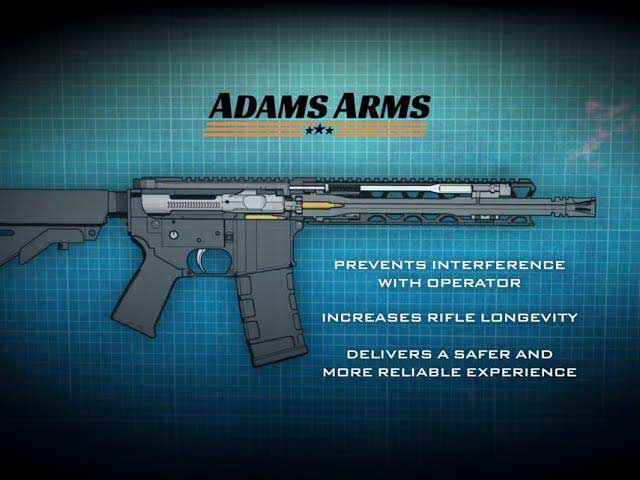

The Adams Arms Retro-Fit Piston Drive System uses the same gas port on the barrel to work the action of our inverted piston. Instead of directing the gases into the receiver, they go into a gas plug and drive rod sleeve invented by Adams Arms. The gases are contained inside the drive rod sleeve and push the bolt carrier rearward using the gas pressure to cycle the action.

Adams Arms proprietary operating systems mechanically actuate the bolt carrier external of the receiver. This keeps the internal receiver and all the critical moving parts clean and free from heat and carbon build up.

Here are some of the main differences when using the Adams Arms Operating System:

- Short Stroke Free Floating Piston System

- Self Cleaning

- Carbon and gases are expelled forward, away from the operator

- Bolt Carrier Group and other critical components remain cool and clean

- Corrosive resistant coating processes

- Harmonics are not transferred into the barrel

- Adjustable gas settings for various applications

- Doesn’t vent direct to atmospheric pressure; this eliminates flash signature and supersonic crack which is optimal for night vision and suppressed fire

Our mission is to meet the engineering and design needs that will improve the flaws of the current AR15/M16 rifle platform for decades to come. There are those that believe the AR15/M16 rifle should be replaced with rifle platforms more recently developed and costing much more than the current rifle now in use. What these companies an/or designers fail to recognize is that there are millions of AR15/M16 rifles already in service around the world, whether owned by private citizens, military, or law enforcement.

The Retro-Fit Piston Driven System developed by Adams Arms will transform and revolutionize the AR15/M16 rifle into a modern day firearm that will continue to be relevant for many decades to come. Additionally the Retro-Fit System, offered by Adams Arms, will save law enforcement, military, and other consumers thousands of dollars by offering a simple upgrade option, instead of a costly replacement firearm.

Adams Arms designed their Retro-Fit System to be installed easily by the average AR15/M16 shooter. This saves the consumer even more money by not requiring the system to be taken to a gunsmith/ armorer or pay for shipping cost and labor charges to send the firearm to the manufacturer for installation. All of the products Adams Arms manufactures are made right here in the USA and are machined out of high grade steel. Combine that with our proprietary PVD and meloniting processes and our Lifetime Warranty and you have purchased a product you can depend on for years to come.

Adams Arms also prides itself on providing the best customer service to all its customers, no matter what walk of life. Should you have a question, comment, or concern about an Adams Arms product, always know someone will be there to help you anyway they can.